Roof Top Tent Replacement Mosquito Netting

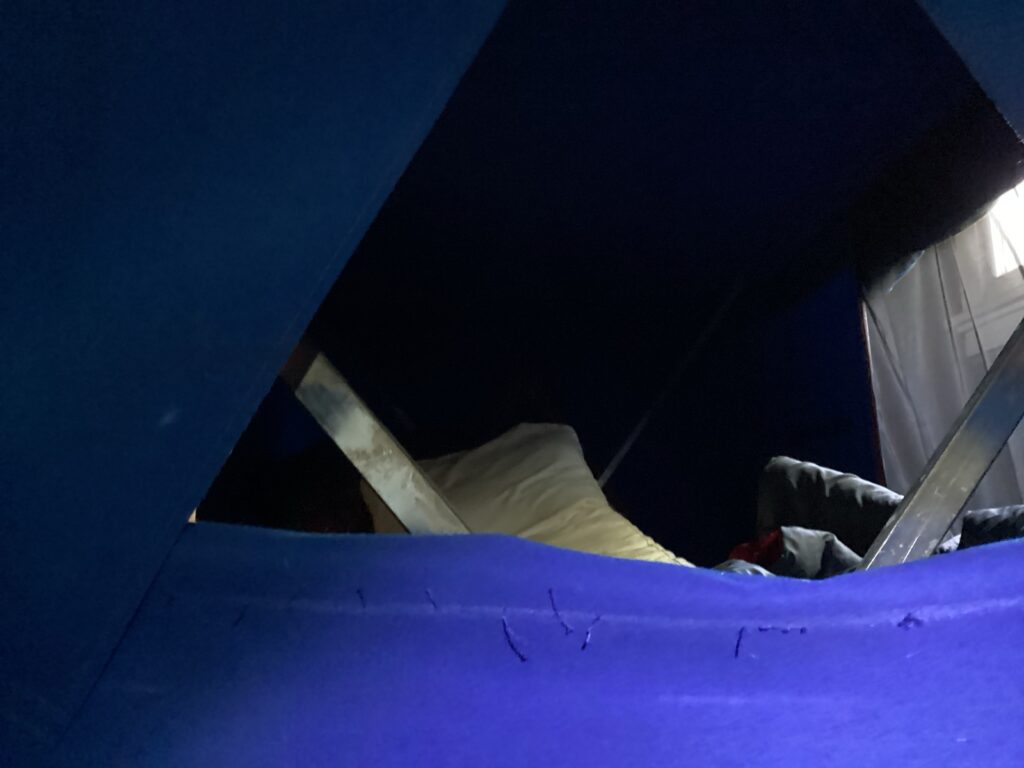

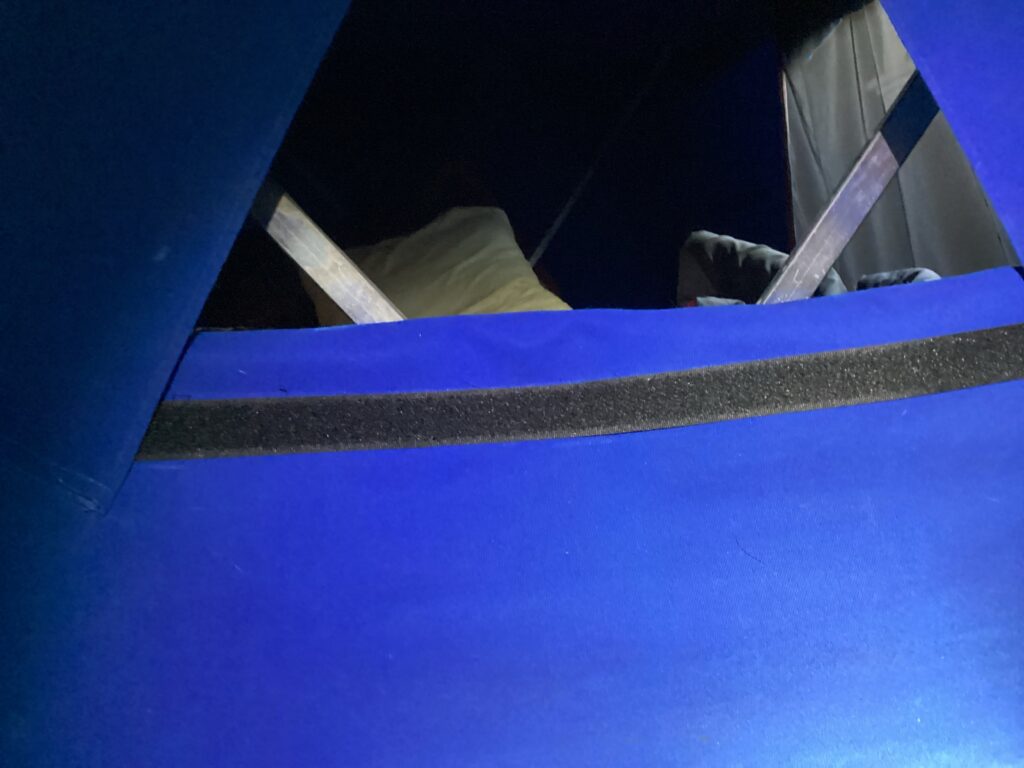

This little project of mine has been years in the making. My Maggiolina roof top tent is an Original 17+ years old. I had to seam rip the old screens out and hand sew hook and loop (Velcro) into the window sides and door headings and onto the doors and windows themselves.

The important takeaway here is that installing this finer weave of a screen drastically reduces airflow. I was prepared for the reduced airflow and this was an acceptable loss for me to ensure improved protection from biting insects.

I can not recommended using nylon made screen material. Nylon has a high propensity for stretching when wet.

I chose to use mosquito curtains fabric polyester.

NOTE: After installing the doors on the tent and leaving it in the garage for 10 days I returned to find holes had magically appeared in one of the doors. I have no idea how the holes got there since the material is suppossed to be rated for exterior use, UV rated and strong enough to hold up a persons body weight.

So after a quick internet search and much to my horror I learned that insects such as crickets or locust can easily chew their way through non aluminum mesh netting commonly used for home and tent window screening. So to combat this from ever happening again I will soak all of the screen doors and windows in permethrin on an annual basis and then lay them flat to spray them with insect repellant.

I did reached out to the company and they offered to replace the screen material

I used a seam ripper to remove the screen doors. I added hook and loop to the header before installing the new screen doors so that replacing the doors in the future is easier.

Next the windows

I used fabric tape to help hold the hook and loop in place while hand sewing it into the tent.

First piece sewn in for the window!

I used the old window as a template. Paying special attention to sew the bottom hook and loop on the outfacing side of the screen and the two vertical pieces on the interior facing screen.

Planning Phase

Available Materials

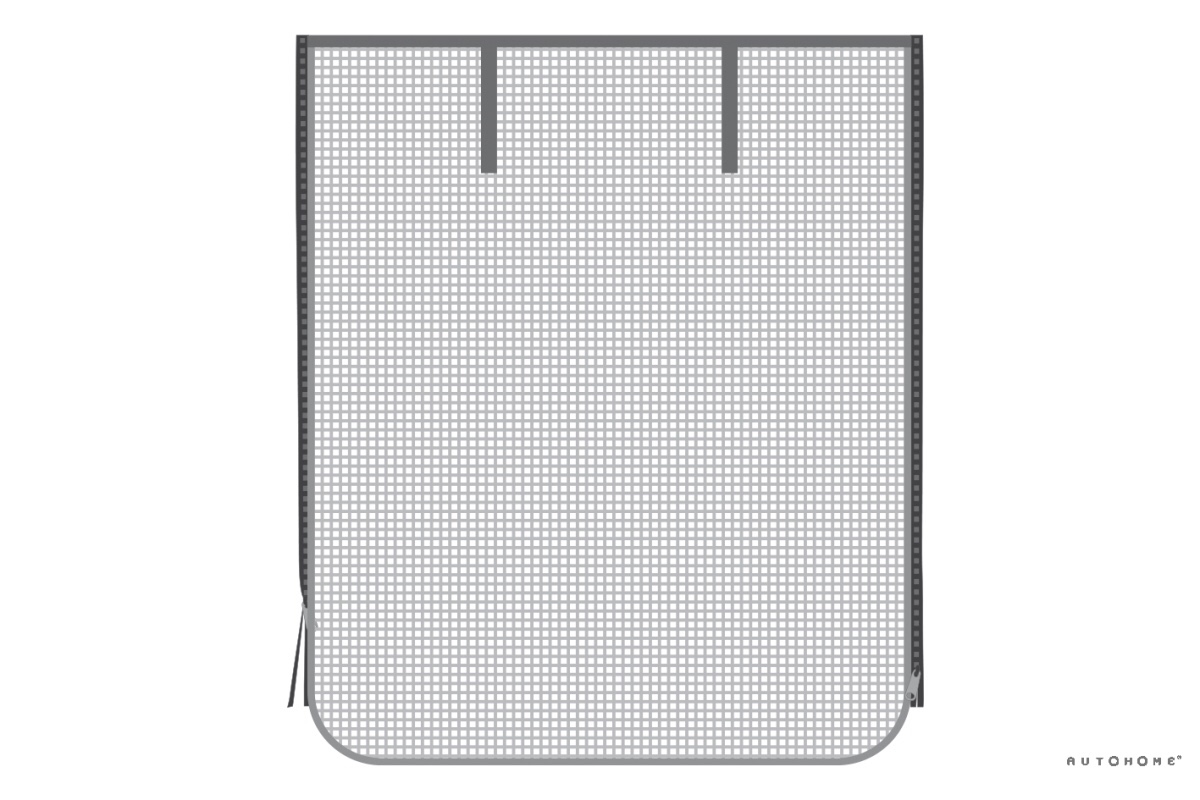

I am getting ready to improve upon the mosquito netting in my 17+ year old Autohome Maggiolina roof top tent. The current window and door screens are rated as mosquito repelling only which means that the smaller mosquitos, gnats and bugs can easily pass through.

Please note that it may be possible to buy replacement mosquito screen windows and doors by contacting the USA Autohome. It might be less expensive to buy these already made rather than making them yourself if you do not have a sewing machine. The issue is the mesh size is too large to stop smaller insects.

When it comes to sewing most fabrics fall into certain weight categories Ex. Drapery fabric and upholstery fabrics are one in the same and are heavier thicker fabrics that are identified by their weave and weight versus fabrics that are used to make apparel or tote bags which are also identifiable by weight and intended use. When searching for drapery or upholstery fabrics they are identified as such and easily located on websites and within fabric supply stores.

This same guiding principal seems to be non existent when it comes to identifying the no see um mesh. Not many no see em fabrics are made for exterior use which means they will not hold up to UV exposure and the elements. These fabrics appear to be popular for decorative porch curtains. A lot of the fabrics used in tent making are extremely light weight and easily punctured or torn.

For the strongest screen replacement it’s a good idea to choose a material with minimal stretch to reduce tears from normal handling. Lastly a material that maintains its structural form will be easier to roll up out of the way as well as not snagging and tearing.

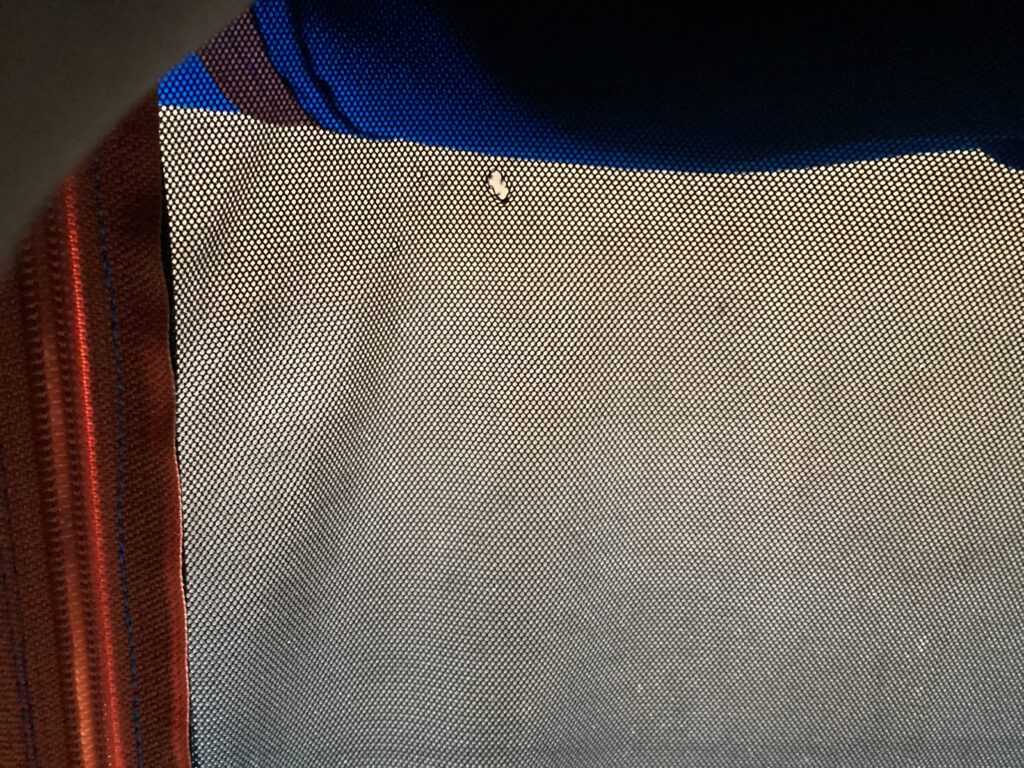

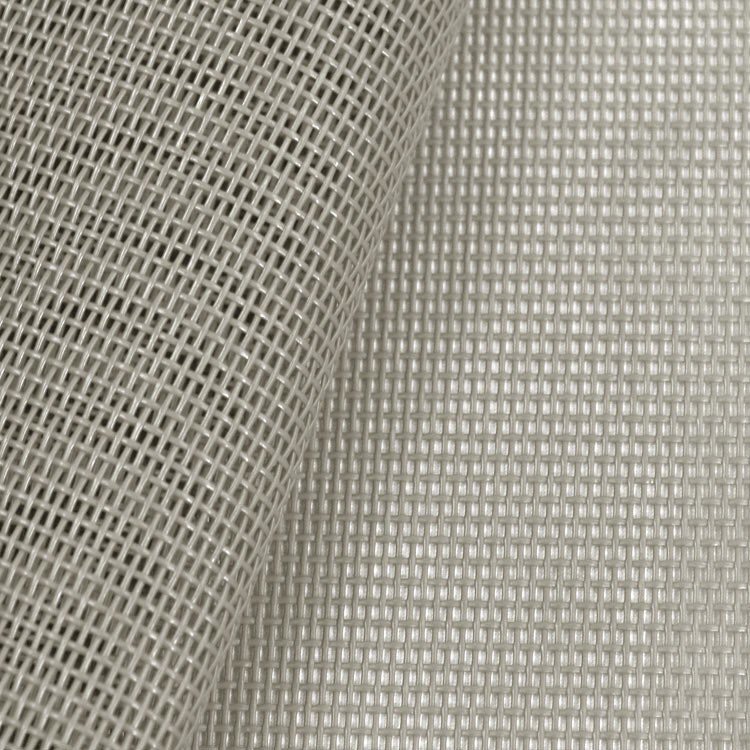

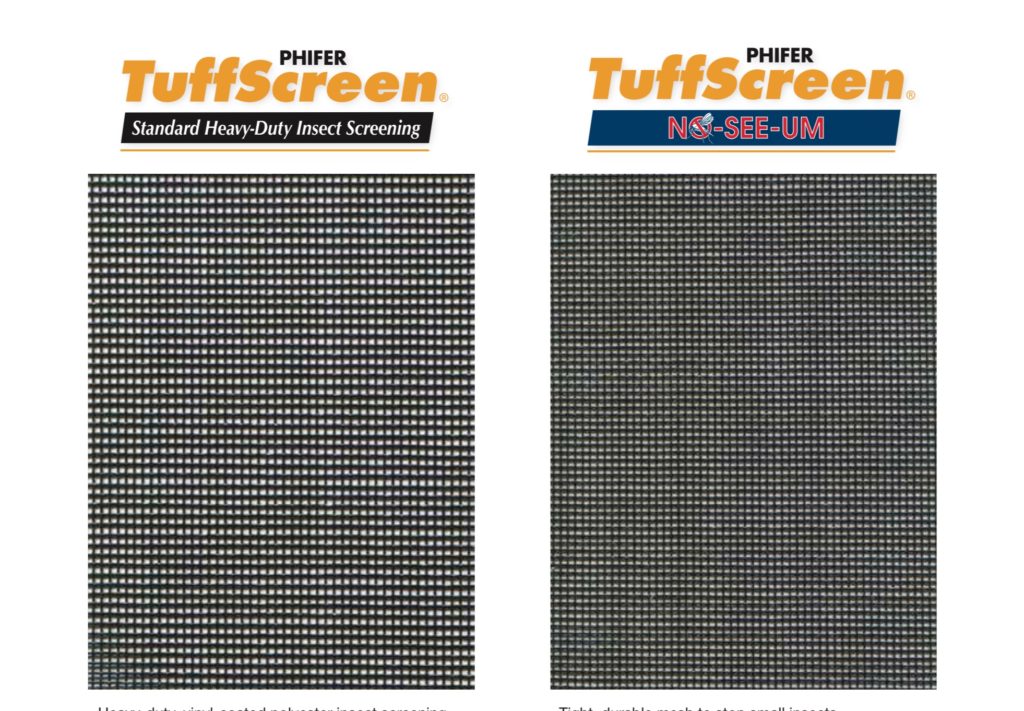

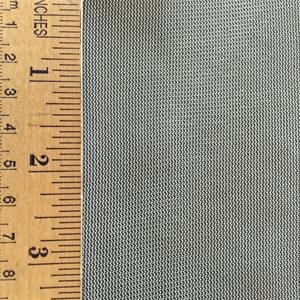

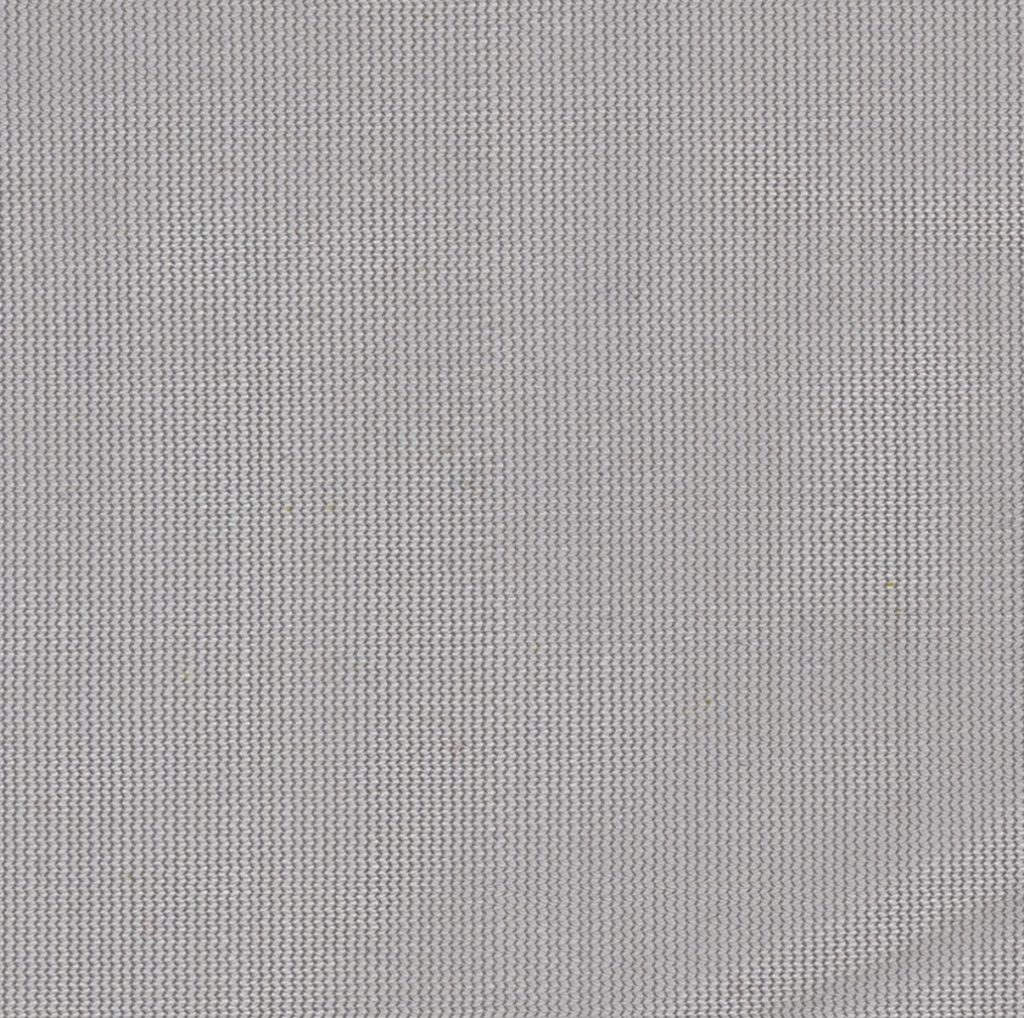

Phifertex Standard Mesh Netting

If looking to make a like kind replacement then the Phifertex Standard Solids, Here it is shown in Gray, seems to be a perfect match. Phifer has two manufacturing distributor locations #1 is Italy and #2. LA California. It is a very good chance that this is the exact material that is used by Autohome in making the roof top tents original older screens.

Pro TIP: darker colors are easier to see out of and lighter colors are more difficult to see through. Watch Video Here!

- 54” Wide

- 100% Polyvinyl Chloride Coated Polyester

- 17 x 11 mesh construction

- 11.7 Oz Per Square Yard

- Grab Tensile:385 x 255

- UV resistant, Mildew & Fade Resistant, Stain Resistant, Tear Resistant, Heat Sealable, Flame Retardant

- 3 year warranty

- Largest selection of colors

- samples are available

No See Em Mesh Netting

In order to be classified as “No see em” mesh netting it must have a minimum of 600 holes/sq in and it is optimal to have a cross hatch weave but not necessary. Important details to look for when buying No see em mesh netting are;

- 20 x 20 mesh construction or 600 Holes/ sq in or greater

- Denier (thread thickness) > 20

- Tensile strength (the amount of force to break the thread)

Weight 0.67oz/sq yd= stuff sacks or light weight apparel.

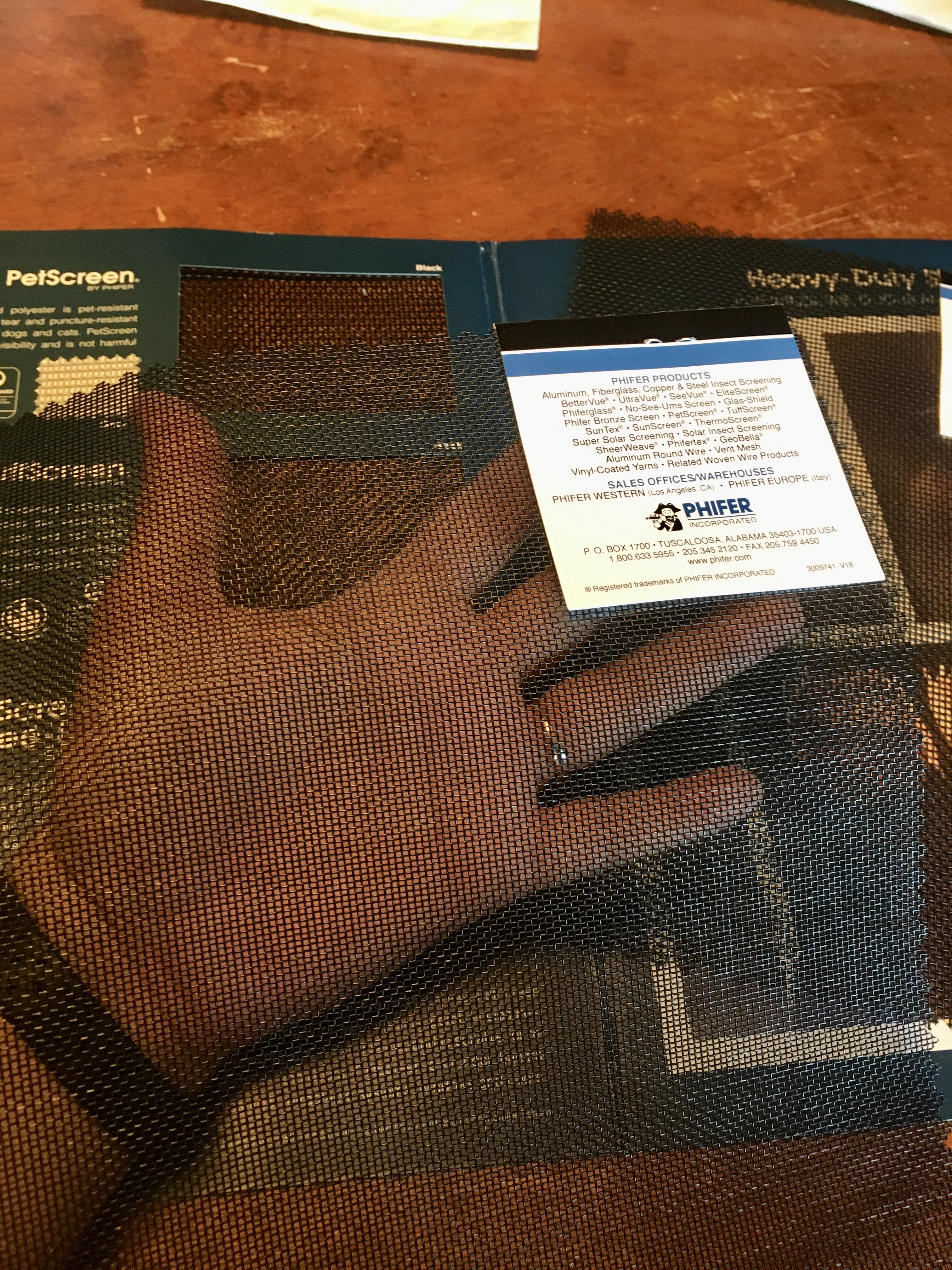

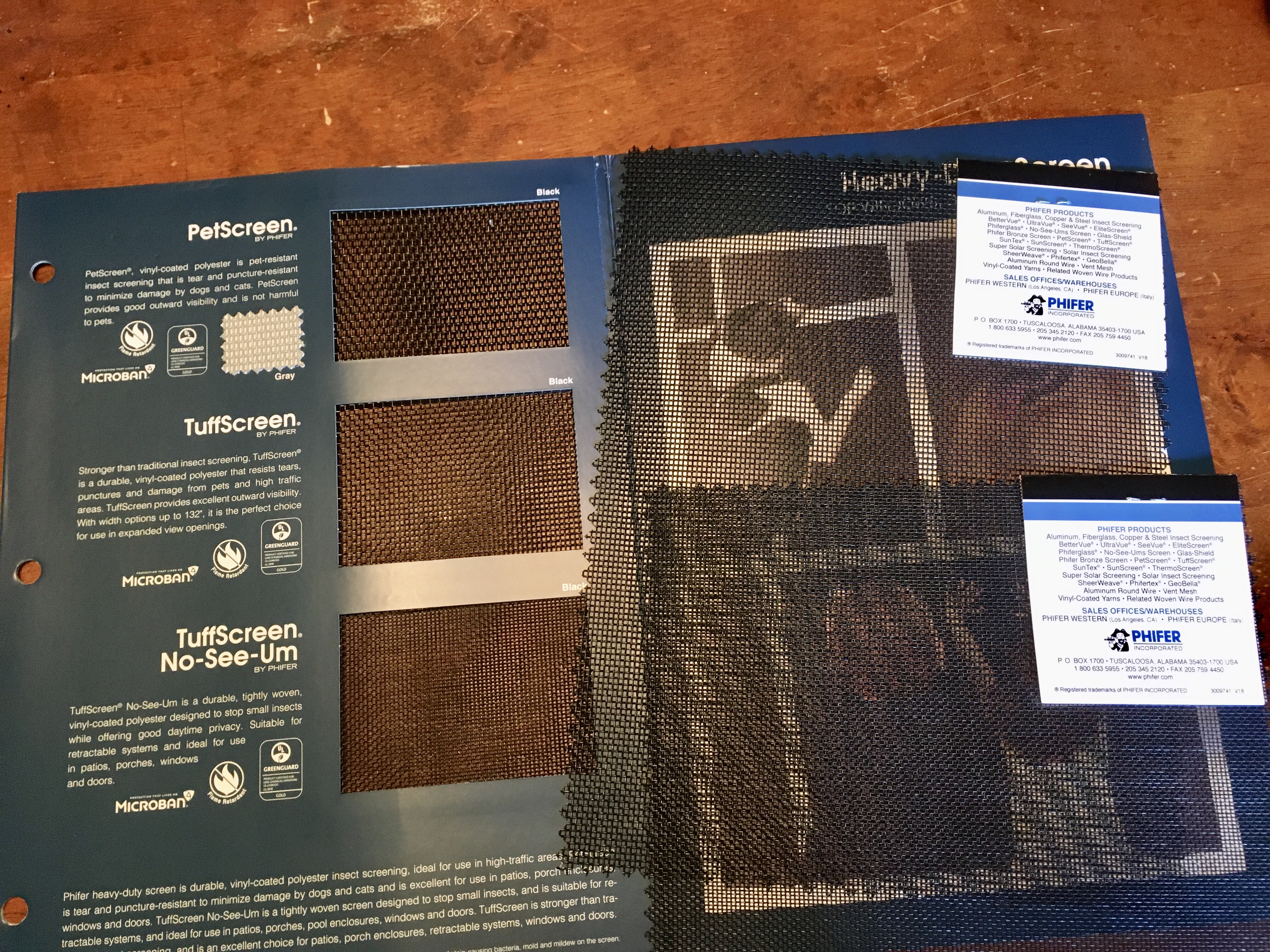

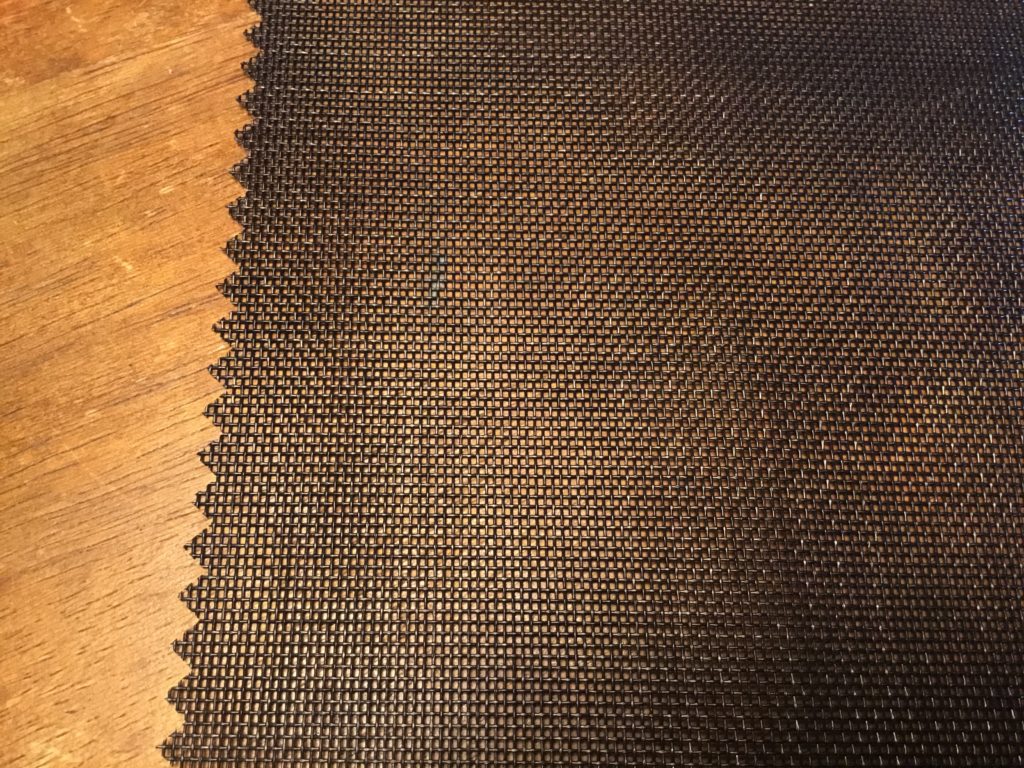

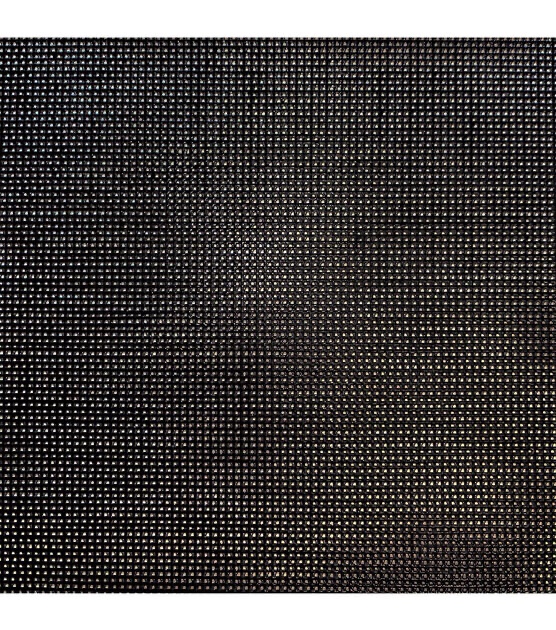

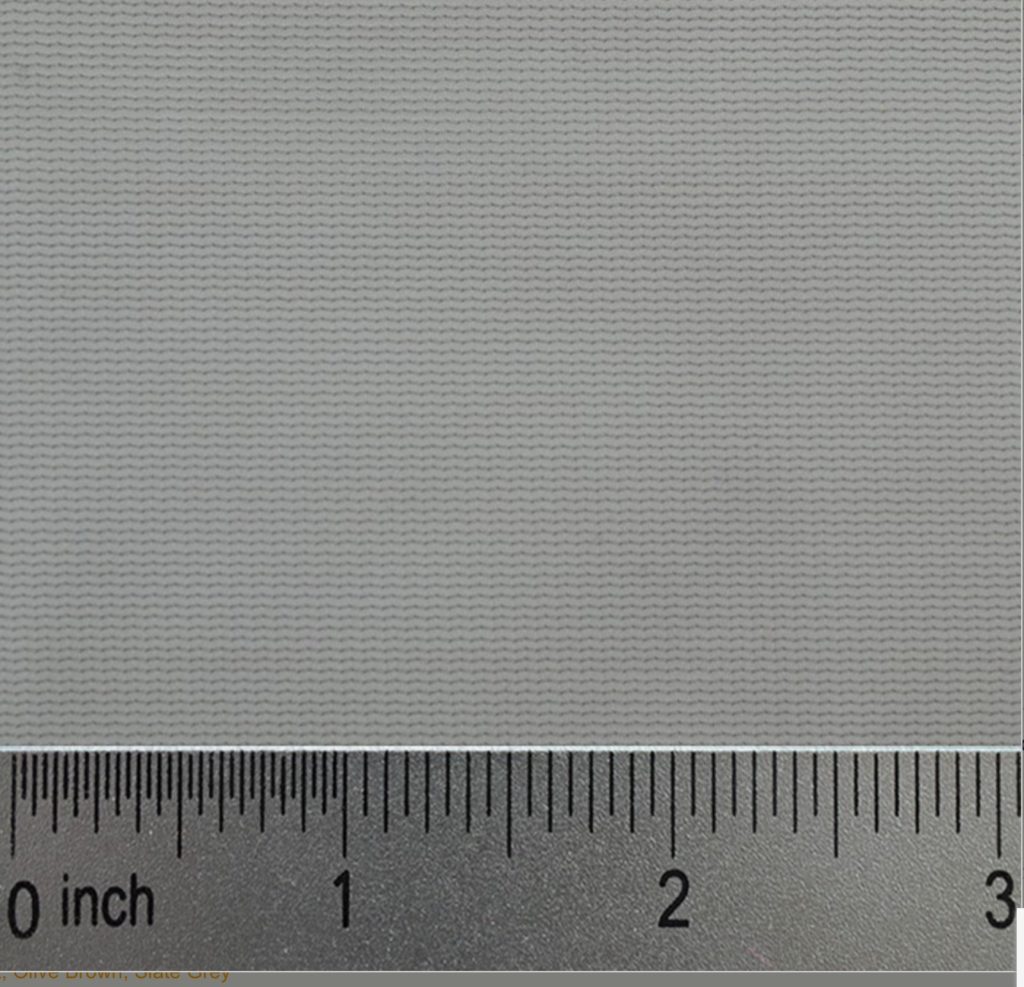

TuffScreen® No-See-Ums

My only complaints are that the material is only sold in 50ft rolls thus making it financially unrealistic for the small quantity that I need. Second there are a few reviews saying that no see em insects still get through. This would be my #1 choice for replacing my rooftop tent screens if it weren’t for these two issues.

This by far is the most impressive, durable, strongest feeling screen material. It is a polyester coated screen mesh that is UV resistant, mildew and mold resistant and made to withstand the outdoor elements!!

This material is not for sewing into clothing or apparel and it has the same exact texture and strength as my existing screen material. It has a firm structure to keep its form and zero stretch and zero drape. I was satisfied and impressed with the sample pack I received. I also received samples for the Tuff Screen and Pet Screen.

Stronger Than The Unpredictable

Phifer TuffScreen is heavy-duty, vinyl-coated polyester insect screening that is ideal for use in high traffic areas. Yes, the most common purpose of screening is to keep bugs out. However, keeping bugs out is nearly impossible if your screens are ripped from anxious pets, rambunctious children, pesky wildlife or harsh weather. TuffScreen® heavy-duty mesh screening is made from vinyl-coated polyester, making it tear and puncture resistant, and one of the most durable screen options on the market. It installs just like regular screening but is three times stronger than standard fiberglass, and won’t need to be replaced nearly as often. We’re so confident in our heavy duty screen material’s ability to protect your windows, doors, porch and pool enclosures that we offer a 10-year warranty.

- Black Only

- Multiple sizes

- Polyvinyl Chloride Coated Polyester

- 6-7 oz/sq yd

- Yarn Diameter (inch): .013 Warp / .013

- Fabric Thickness (inch): .021

- Bond Strength (lb): 31

- Openness (%): 42

- Mullen Bursting Strength (psi): 163

- Mesh Count: 18×22

- Free Samples!!

- Only sold by the bolt!

- Limited 10 year warranty

TIP: if you want to know what this feels like and have a Joann Fabric store nearby check out their coated mesh fabric. This material is used to make swim gear bags, snorkel gear bags, travel utility bags. It does not offer decent visibility and has in my opinion a heavier weight and thicker vinyl coating.

MosquitoCurtains.com

This is the Fabric I chose to work with and holes appeared presumably from insects chewing their way through.

This material is made up of a small honeycomb pattern. I was impressed by the sample pack I received. The no see em feels extremely durable, tough, and perfect for sewing into light weight tents, hammock mosquito covers, backpacking mosquito covers, clothing, head covers, etc… and not worry about tears. This fabric drapes and rebounds to its original shape without creasing or wrinkles. There is a slight bit of stretch to this material. Zero fray from the cut edges! This material is too light weight to keep its form when rolling up for use in our Autohome door screens so I will need to add a thick 1” nylon bias to the boarder.

- 101 in Or 123 in wide

- 800 holes / sq in

- 2 oz / sq yd

- Denier 225

- Air flow 65%

- Clarity Black: 94%

- 0.6 mm x 0.6mm hole size

- Smallest amount to order is 5ft

- 2 color options (white/Black)

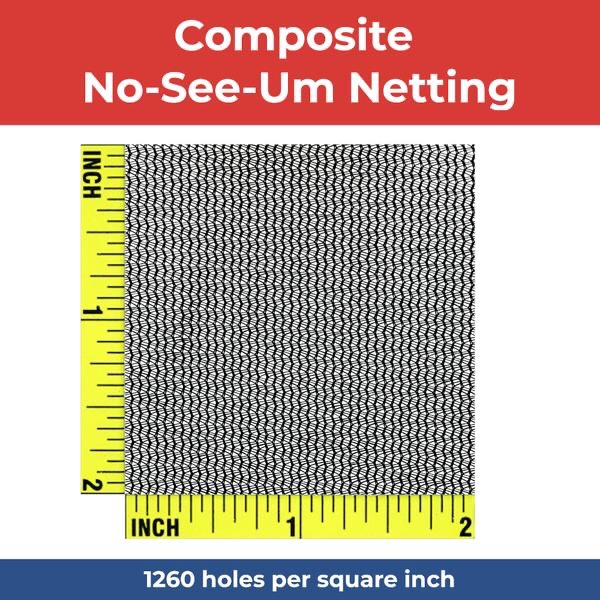

Mosquito Net USA

In the event that my first choice material does not hold up to normal use than this is my second choice for material.

I was unimpressed when I received this sample because there was nothing to identify where it had come from. The material is a silky soft smooth polyester and easily drapes and feels like a heavy weight mesh netting. This material requires a bit more skill and fitness when measuring for exact cuts to ensure it will maintain its form once installed.

There is a crease in the sample material that does not want to flatten out and there are frayed edges that would require the use of a heat cutter to prevent any future fraying. I did not use this in my rooftop tent for fear of ripping and tearing holes into it. It is a great looking fabric and if I weren’t worried about it getting caught and ripping in the scissor lift of the rooftop tent or tearing when caught in a zipper than I would use this.

Overall though the technical features of this fabric are impressive with allowing 70% airflow, marine grade treatment, and being 2.24oz/sq yd.

- Black Only!

- Custom Width!

- polyester composit

- 2.24oz/sq yd

- 1260 holes/ sq in

- Marine Grade Treated

- Tensile strength: 80

- Visibility: 75

- Airflow: 70

- offers Free Samples

Here are some other available options on the market worth mentioning. I decided that these just wouldn’t be suitable and strong enough for my particular needs.

Sailrite.com No‑See‑Um Mosquito Netting Black UV Treated 72″ Fabric

- Content:100% Polyester

- Fabric Design:Solid & Variegated

- Color:Black

- Weight: 1.95 ounces per square yard

- Special Features:UV

- ResistantCertifications:California Prop 65 Compliant

- Roll Size:200 yards

- Flexible Mesh:24×23

- Holes Per Square Inch:552

Light Weight & Uncoated No SeeEm

Skeeta

No-see-um “Military” Grade Berry Compliant Fine Mesh Netting By The Yard – 64″ wide

- 54” & 64” wide

- Polyester

- Weight: 1.9oz/yd2

- 1,800 Holes/sq in

- tensile strength: unavailable

- Denier: 40

- 5 color option

- This company offers multiple colors

Canvastec

Weight: .85 ounces per square yard

Width: 54″

Content: 100% polyester

Coating: None

Finish: Dyed

Yarn: 100% Polyester 20D Stabilized

Color: Black

Weave: Tricot Knit 1054 holes per square inch

Campmor

- 72” wide

- Polyester

- 625 holes per square inch.

- Weight = 3.2 oz. per Yard

- Denier: 20

Fabric.com

- 54” wide

- Nylon

- 1.1oz/yd

- Holes/sq in: unavailable

- Tensile strength: unavailable

Seattle Fabrics

- 54” Wide

- Polyester

- 1oz/yd

- Denier : 20

- Holes/sq in: unavailable

- Tensile strength: unavailable

- Allows for ordering less than a full yard!

- 5 colors available

RockyWoods

- 54”-55” Wide

- Nylon

- 0.96 oz/sq yd

- Tensile strength: unavailable