DIY N95 Masks Medical Polypropylene Face Masks

This page is about the information and understanding of what goes into making a home made mask and its efficacy.

To see my guide on how to make an effective antiviral face mask see my post on DIY FACE MASK!

I am a registered nurse with growing concern about the spread of miss information. In any case I seek to be well informed. The problem at hand is that our nations medical professionals are broaching the cusp of running out of personal protective equipment and a vast amount of miss information is being spread among both the general public and medical professionals. So in preparation of personally needing these face masks for working direct patient care in the hospital setting I am here once again back to the drawing board to understand what exactly is happening.

Question: Can n95 masks be reused?

Answer: yes with a full face shield and or a DIY cotton mask cover changed in between each patient.

Question: Can a mask be shared?

Answer: In ideal situations, no. This is cross contamination due to the increased humidity inside the mask.

Question: do I need to wear an N95 mask when the cdc is recommending surgical masks?

Answer: All scientific peer reviewed journal publications I have read say, Yes!

The CDC is rolling back safety recommendations in light of personal protective equipment supply shortages. Please keep in mind that the CDC is constantly battling releasing new policy and guide lines to compensate for mask shortages. In a perfect world our government would have quickly rallied behind our nations medical system by activating our countries existing manufacturers to step up and make more supplies for our hospital systems. Instead we have hospital administrators confiscating PPE from front line nurses and doctors to put under lock and key and ration.

Update 3/26/20: It appears that Duke Health Research has discovered a viable method for sanitizing and reusing N95 masks. According to the article this method can not be done at home and requires specialized equipment.

Current public made DIY masks can not protect medical professionals against COVID19 100%. By the current standards it is extremely difficult to make a professional grade mask. These DIY sewing masks are meant to be used over the top of medical grade masks and or paired with a full face shield.

Incorrect use and disposal of masks and PPE may actually increase the risk of pathogen transmission, rather than reduce it, especially when masks are used by non-professionals such as the general public.

So in the rest of this article I will look closely at each element that goes into making a medical grade mask and evaluate each step along the way to determine if this can be accomplish or if it is a dead end and a waste of everyone’s time.

Let’s start at the beginning, the CDC page: Strategies for optimizing the Supply of Face masks. They explain that as a last resort a homemade mask should be used.

CDC Strategy Guide

“Crisis Strategy section, When No Facemasks Are Available, Options Include:

Healthcare personnel (HCP) use of homemade masks:

In settings where facemasks are not available, HCP might use homemade masks (e.g., bandana, scarf) for care of patients with COVID-19 as a last resort. However, homemade masks are not considered PPE, since their capability to protect HCP is unknown. Caution should be exercised when considering this option. Homemade masks should ideally be used in combination with a face shield that covers the entire front (that extends to the chin or below) and sides of the face.”

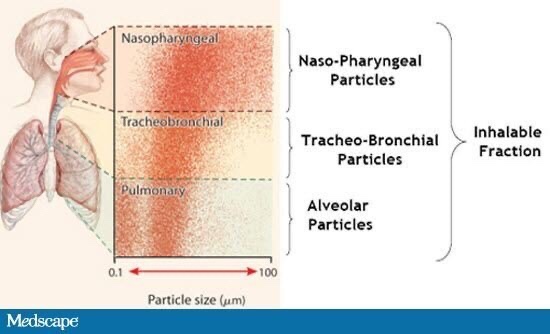

Regardless if the CDC has publicly stated that it does not believe that COVID 19 is being transmitted via aerosol particles it is up to each us to critically evaluate this information. This controversy has arose at the height of an N95 mask supply shortages and possibly in order to quiet growing concerns of the front line healthcare professionals that are being encouraged to work without adequate PPE. This recent development is in clear contradiction of earlier publications such as Controversy: Respiratory Protection for Healthcare Workers. The CDC has in the passed acknowledged that influnneza is transmissible via aerosol “however, the CDC, the Institute of Medicine, and other researchers have found that influenza can be transmitted through the inhalation of infectious aerosols (Harriman, K. H., & Brossesu, L. M. (2011)).”

Reusing a Face Mask

According to the 2006 Institute of Medicine guidelines there is no way that an N95 mask can safely be sanitized. However they can be continuously used if protected from direct contamination by wearing a full face shield. It would appear that in these desperate times many health professionals are putting this to the test and coming up with creative ideas and only time will tell if any of them will work.

The Institute of Medicines 2006 guidelines for reusable mass during an outbreak are

Recommendation 1: Avoiding Contamination Will Allow for Limited Reuse.

If an individual user needs to reuse his or her own N95 filtering face piece respirator, the committee recommends it be done in the following manner:

-

Protect the respirator from external surface contamination when there is a high risk of exposure to influenza (i.e., by placing a medical mask or cleanable faceshield over the respirator so as to prevent surface contamination but not compromise the device’s fit).

-

Use and store the respirator in such a way that the physical integrity and efficacy of the respirator will not be compromised.

-

Practice appropriate hand hygiene before and after removal of the respirator and, if necessary and possible, appropriately disinfect the object used to shield it.

Face Mask Use

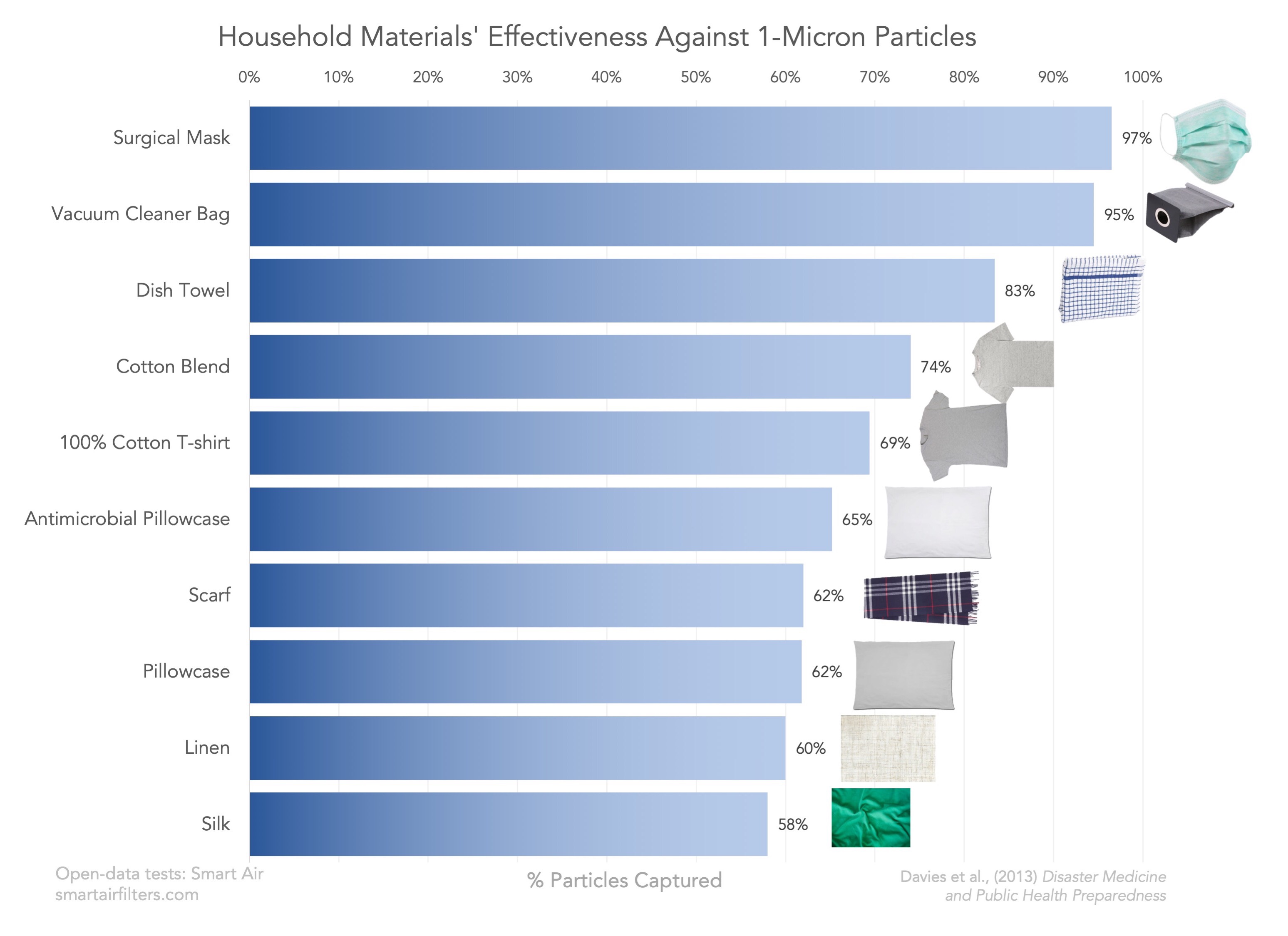

When looking closer at all of the components and ingredients necessary to make an adequate N95 mask it is easy to see the level of difficulty in accomplishing this task in our home settings.A medical grade N95 mask is used by medical professionals to create a complete seal around the mouth and nose, in conjunction with use of additional proper fitting PPE. These items alone do not guarantee safety of the user and require strict adherence to specified training techniques for putting on and removing of these items in order to prevent the spread and contamination of infectious microorganisms. An N95 mask is one small piece of the much larger puzzle and when used, handled, and disposed of improperly provides no more protection than a scarf or bandana and can increase the rate of disease transmission.

N95 Anatomy

An N95 mask is made up of 4 layers and is saturated in citric acid, copper, and zinc. It is made with spun polypropylene, polyester/cellulose, woven polypropylene, and spun polypropylene. Additionally medical grade masks are created to completely seal off the wearers face from any possible aerosolized particles from entering the airway via the mouth or nose. Masks are designed as one link in the chain of defense against disease transmission and is designed to work in conjunction with additional PPE such as eye protection, gowns and so forth.

Using materials found at home it is possible to make protective covers for the medical grade masks which can lead to extending the reusability of the masks in conjunction with using a full face mask and proper eye protection. As for public use I am pursuing alternative options.

Easy N95 Mask Cover

Supplies

- Tightly woven 100% cotton

- Non woven interface (pellon 951 or other non woven interface)

- Pellon 950F stabilizer

- Metal gauge wire (Use coffee bag clips or cut aluminum from bake wear).

- 1/4″ bias tape or twill tape for ear straps

- Pony Beads for cinching ear straps

Sewing pattern and guide…

https://www.craftpassion.com/face-mask-sewing-pattern/

For further information and an in-depth look behind the making of a 4 layer N95 mask please read on.

The Four Layers of the N95 Mask

Making a mask is so much more than cutting out fabric and sewing it together. There are antimicrobial elements needed to be infused into the textiles in order to be effective at keeping the user protected from microscopic and aerosolized particles, the particles produced by a cough or sneeze.

“5.5 Device Description

“The BioFriendT m BioMaskT N95 surgical respirator, Model: Professional (BF-200-3013AN) is flat- folded and expands into a convex-shaped mask with polyamide/spandex elastic head-loops to secure the mask to the user’s face, and a malleable aluminum strip positioned above the nose for a tighter seal around the nose and face. The respirator is comprised of four layers of material: an outer layer of spun-bond polypropylene, a second layer of cellulose/polyester, a third layer of melt-blown polypropylene filter material and an inner (fourth) layer of spun-bound polypropylene (Deusch, 2013).“

“These properties in the design are achieved through the appropriate choice of materials, such as cotton, polyester, polypropylene, blends, bioactive fibers, and fabrication technologies such as weaving, knitting, and nonwovens (Institute of Medicine. 2006)”.

N95 Mask Active Ingredients

“The BioFriendTm BioMaskTm N95 surgical respirator is a single use NIOSH-approved, disposable N95 surgical respirator with a hydrophilic plastic coating on the outer layer (active ingredient: citric acid 2% w/w, a pH-lowering agent), and a second inner layer treated with metal ions (active ingredients: copper 1.6% w/w and zinc 1.6% w/w which form ionic bonds with negatively-charged side-groups on influenza viruses)(Deusch, 2013).”

HVAC Air Filters

Maybe you have noticed people taking and cutting up the HVAC air filters to use as mask filtering materials. The reason is that certain filters advertise anti viral electro magnetic filtering abilities. This is due to the impregnating of metals such as zinc and copper into the filter fabric during manufacturing. While this might seem like a good idea please keep in mind that the potency ratio of infused electro magnetic elements into these filters is based on the filters intended use to be used as a whole unit with all of the other filter sheets in place and not cannibalized and broken down for alternative uses. Without knowing the ingredient ratio of each sheet within the filter it is impossible to verify the safety in using these materials. Alas from what minimal searching I did I couldn’t readily find an active ingredients list for this product.

Tissues as Mask Filters

Tissues as Mask Filters

Some tissues include an anti viral agent in the manufacturing of their 3ply tissues. This ingredient is citric acid and is not found in all tissues. To tissue box must clearly say “Kills 99.9% cold and flu virus”. The use of any and all other non anti microbial tissues will not offer the same protection.

Infusing Anti viral components into the DIY Mask

What not to do… One YouTube video shows making a “mask” out of a bra and using a coffee filter to add dry powder citric acid that sinks to the bottom of the filter and offers no protection to the user. Additionally the bra mask offers no face seal and is considered for entertainment and novelty purposes only and as a guide of what not to do!

A 2011 scientific publication indicates that it is possible to infuse 100% cotton with anti microbial element using Citric acid and non ionic surfactant.

The 2011 research study on Cotton textiles modified with citric acid as efficient anti-microbial agent for prevention of nosocomial infections, discovered that citric acid can effectively be impregnated into 100% cotton and treated dried with the use of a 900W microwave using 2.45 GHz. The results showed an effective re usable and washable face mask that is effective for up to 10 wash cycles.

“Citric acid (CA) and sodium hypophosphite monohydrate (SHP). Solution of 7% CA and 6.5% SHP solution with ~ 100% wet pickup. dry and cure the fabric using the microwaves at 900 W for 20 minutes (Bischof Vukušić, Flinčec Grgac, Budimir, & Kalenić, 2011)“.

Furthermore…

“Typically the weight ratio of acidic polymer:organic acid in the filter material may be in the range 10:1 to 1:1, preferably 3:1 to 1:1, for example 2+/−0.25:1.

For example the filter material may incorporate one or more surfactant. A surfactant can facilitate wetting of the filter material. Airborne pathogens such as virus are known to be carried in small droplets of water, and consequently enhanced wetting of the filter material can enhance the effective contact between the pathogen and the active materials on the filter material. Furthermore surfactants are known to be effective in disrupting the membranes of virus and bacteria. Non-ionic surfactants are preferred because ionic surfactants can tend to cause the acidic polymer to gel. A preferred non-ionic surfactant is selected from the Tween™ or Polysorbate™ family of surfactants (Jul 16, 2007. (n.d.). Anti-Viral Face Mask and Filter Material (Jul 16, 2007)).”

- 16oz solution

- 7% citric acid

- 6.5% surfactant

16oz x Y = 7%

Y=1.12oz

16oz x Y = 6.5%

Y= 1.04 oz

***For 16oz citric acid solution mix 1.04oz of surfactant with 1.12oz of citric acid into 13.84oz of distilled water.***

(I knew all of these nursing math requirements might pay off some day for more than just building things around my house).

Absorption Method

Begin by completely emerging the cut piece of cotton into the citric acid mixture. Allow the fabric to sit in mixture until it becomes completely saturated. Hang item to drip dry.

Surfactant

I use surfactants in my garden every year to assist in home made pesticides sticking to plant leafs. It is a surface active ingredient that aids in reducing the surface tension of a liquid (Mason, Sarah. (n.d.)). Non ionic surfactants can also be found in house hold cleaning solutions.

Things You Will Need

- Dawn dish soap

- Has both ionic and non ionic properties that can be used as a surfactant.

- Tween™ or Polysorbate™

I want to adhere to recreating the original study results as closely as possible. So I will be using Polysorbate 20 from here. For larger orders buy here.

Zinc & Copper

This step is where things run into a dead end. According to studies it is possible to infuse 100% cotton with metallic components such as zinc and copper. The cotton masks efficacy were found to be viable for up to 20 wash and drying cycles. The issue arises of how to infuse the zinc and copper into the fabric? I did not find a good method for doing this at home.

The fabric coating process includes dip-coating, sol-gel, electro deposition, and chemical bath deposition (Verbič, Gorjanc, & Simončič, 2019, p. 4).

https://www.sciencedirect.com/science/article/abs/pii/S0144861719300876

https://res.mdpi.com/d_attachment/coatings/coatings-09-00550/article_deploy/coatings-09-00550.pdf

https://journals.sagepub.com/doi/abs/10.1177/0040517510397577

“Impregnation of copper oxide into respiratory protective face masks endows them with potent anti-influenza biocidal properties without altering their physical barrier properties. The use of biocidal masks may significantly reduce the risk of hand or environmental contamination, and thereby subsequent infection, due to improper handling and disposal of the masks (Borkow, Zhou, Page, & Gabbay, 2010).”

**DISCLAIMER. This DIY design that I am sharing here has not been tested in this combination and is not recommended as tested and proven to protect against COVID19 or any other infectious diseases.**

Face Mask with Pocket

This was a great idea when I saw this posted in a group discussion but in all honesty the practicality of using something like this just wasn’t practical to the typical public without a 3D printer.

this handy black plastic piece can theoretically create a full face seal when sewn into a DIY pocketed face mask. I saw this on Facebook here. I do not have one of these in my possession so I will try using alternative items.

this handy black plastic piece can theoretically create a full face seal when sewn into a DIY pocketed face mask. I saw this on Facebook here. I do not have one of these in my possession so I will try using alternative items.

How to Wash and Clean Polypropylene Filters

Follow the directions offered by the manufacturing companies when you buy your material. Here are a few recommendations I found for the items I have listed.

“For bags that are made of composite man-made fibers like nonwoven polypropylene and recycled PET, hand wash or use the gentle cycle on your washer. However, this is the one time that hot water should always be used when washing by hand or on the gentle cycle. These bags should never be put in the dryer on high heat. Allow them to air dry.” Information found here.

Pellon 830 Care: Machine wash cold, Delicate cycle & Dry low heat.

Felted polyester Care: No chlorine bleach, Tumble dry low & Cool iron

Polypropylene

I was amazed after buying polypropylene that I knew exactly what it was because as a healthcare professional it is everywhere.

Sewing Tutorials

https://www.craftpassion.com/face-mask-sewing-pattern/

https://www.instructables.com/id/DIY-Cloth-Face-Mask/

https://youtu.be/VgHrnS6n4iA

Sources

Bischof Vukušić, S., Flinčec Grgac, S., Budimir, A., & Kalenić, S. (2011, February). Cotton textiles modified with citric acid as efficient anti-bacterial agent for prevention of nosocomial infections. Retrieved March 23, 2020, from https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3046493/

Borkow, G., Zhou, S. S., Page, T., & Gabbay, J. (2010, June 25). A Novel Anti-Influenza Copper Oxide Containing Respiratory Face Mask. Retrieved from https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0011295

Deusch, K. (2013, May 18). PDF.

Harriman, K. H., & Brossesu, L. M. (2011, April 28). Respiratory Protection for Healthcare Workers: A Controversy. Retrieved March 24, 2020, from https://www.medscape.com/viewarticle/741245_3

Institute of Medicine. 2006. Reusability of Facemasks During an Influenza Pandemic: Facing the Flu. Washington, DC: The National Academies Press. https://doi.org/10.17226/11637.

Jul 16, 2007. (n.d.). Anti-Viral Face Mask and Filter Material. Retrieved from https://patents.justia.com/patent/20090320849

Mason, Sarah. (n.d.). How to Make Surfactants for Plants. Home Guides | SF Gate. Retrieved from http://homeguides.sfgate.com/make-surfactants-plants-81625.html

Verbič, A., Gorjanc, M., & Simončič, B. (2019). Zinc Oxide for Functional Textile Coatings: Recent Advances. Coatings, 9(9). doi: 10.3390/coatings9090550