Aqua Cube Companion Base Camp Shower- Error Code E1

This particular shower was mass produced in China across multiple brand names including companion aqua cube Logic, base camp Mr. Heater Aqua Cube, hike crew, cost way, etc.. in multiple countries. So there are multiple varying owners manuals with different degrees of information. In the Northern American owners manuals (Mr. Heater) you can find the complete build schematics with identifying part names and in another it shows a full electrical diagram. Owners manuals for Australian consumers are the least helpful and do not contain any pertinent useful information to aid consumers in continued maintenance and repairs.

If there was an issue that required parts and I could not source them online or from aliexpress and or modify ones myself then I would reach out to local plumbing and hvac stores and if that did not work I would reach out to local metal fabrication and welding shops as it is very likely an existing part may simply need to be bent into the correct shape to fit.

Aqua Heat Shower: I am extremely disappointed in the Companion Aqua Heat shower which has been rebranded in Northern America under the name Kakadu. #1. The owners manual is abysmal and lacks any electrical or parts schematics. #2. They claim a 3 year warranty but hide the fact that it is a limited warranty. If the company had confidence in the product they would offer a 3 year full or express warranty! Sure the Aquaheat has a smaller footprint and very likely has the identical build design but at a cost of $500+ it doesn’t even come with a storage bag and the gas regulator is built in which means if it fails the unit needs to be disassembled to access it. Also with the smaller foot print you lose anywhere to put your clean clothes.

I reached out to companion in Australia and Hike Crew to find out if I can still order replacement parts. Companion said no and Hike Crew never responded. I suspect that I would need to source the parts myself or have them repaired or rebuilt. This is merely a rough plan I put together to tackle finding the culprit of my issue.

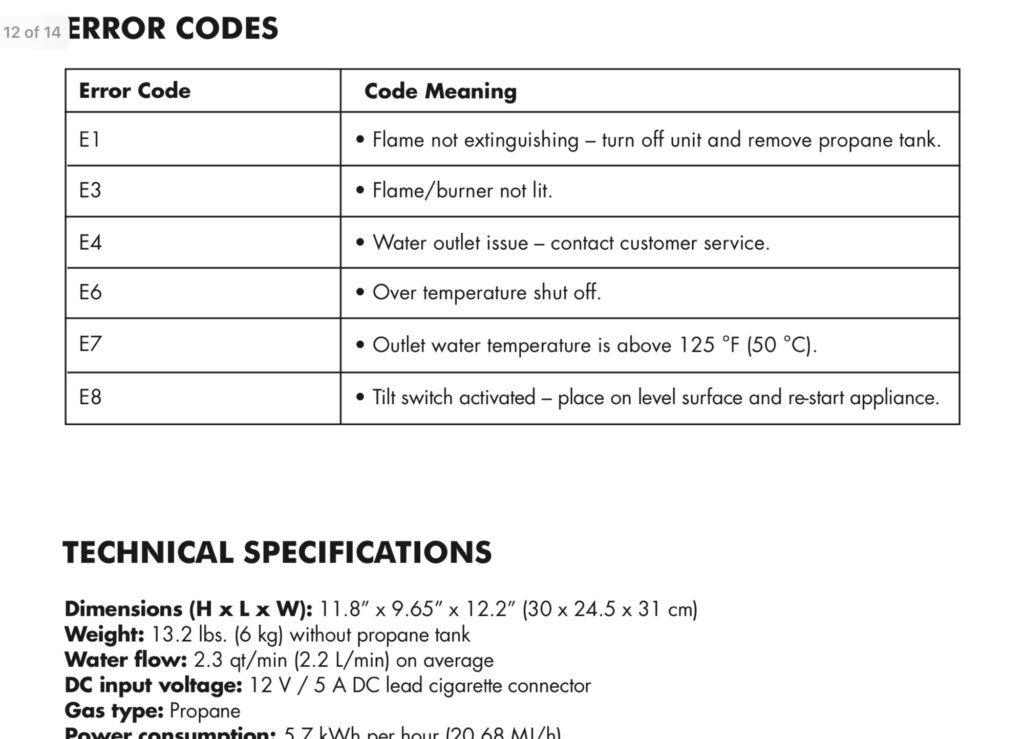

E1 error Code

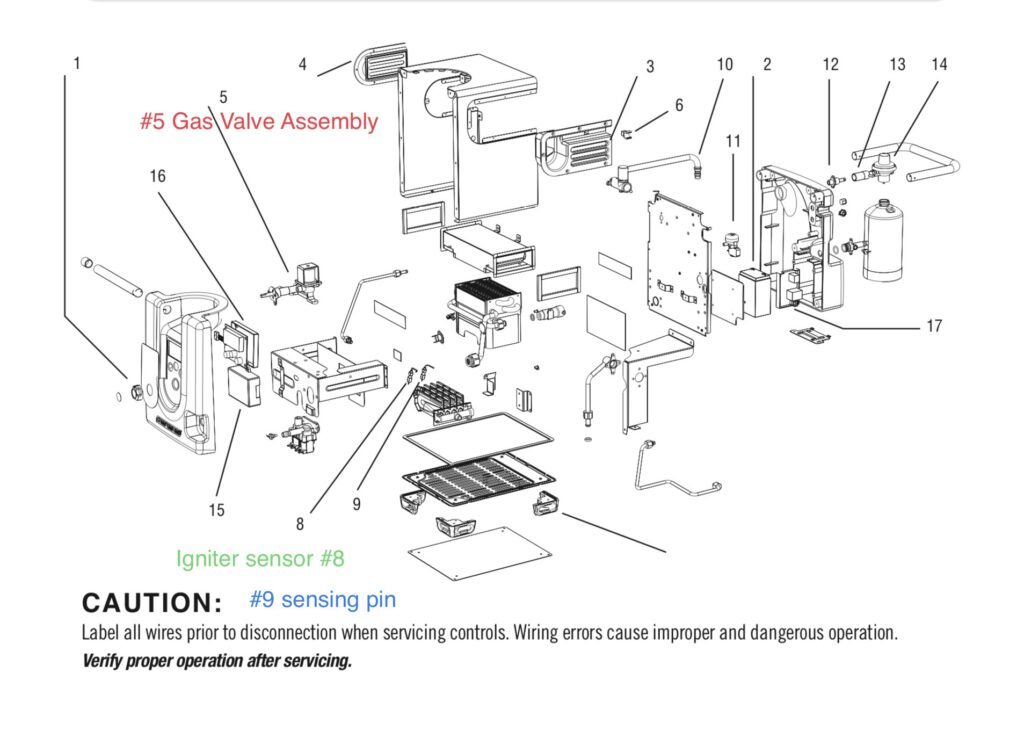

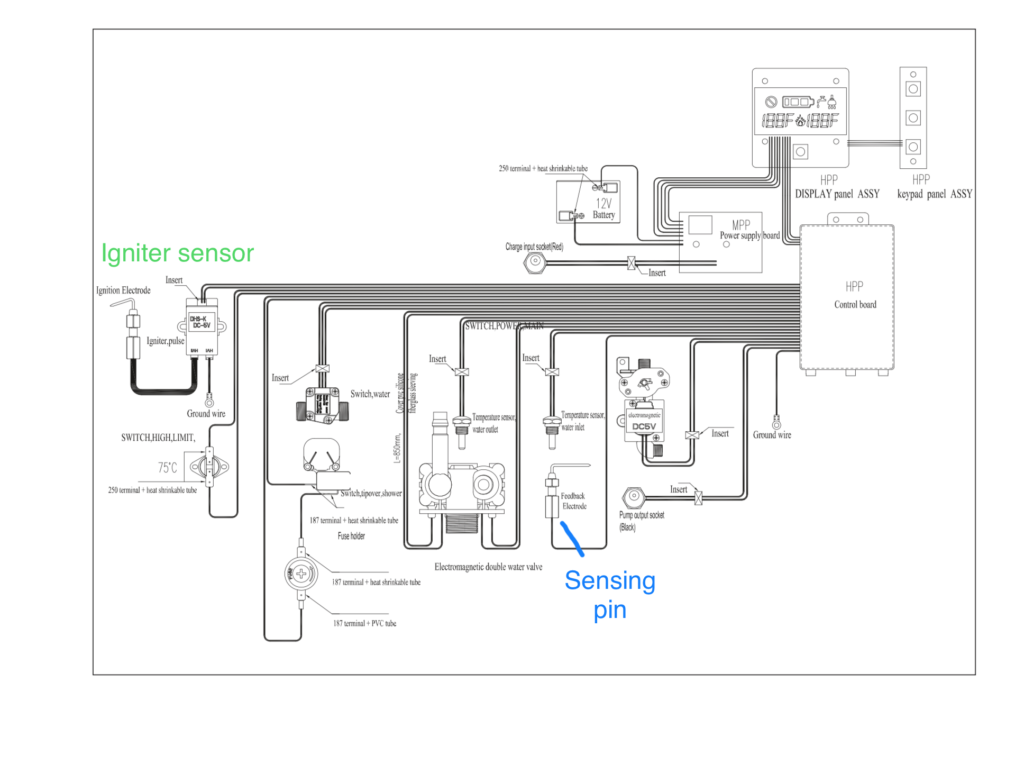

E1 error code is “flame sensor error” and in another it shows as “flame not extinguishing”. The flame sensor is the igniter Sensor #8 in Diagram A.

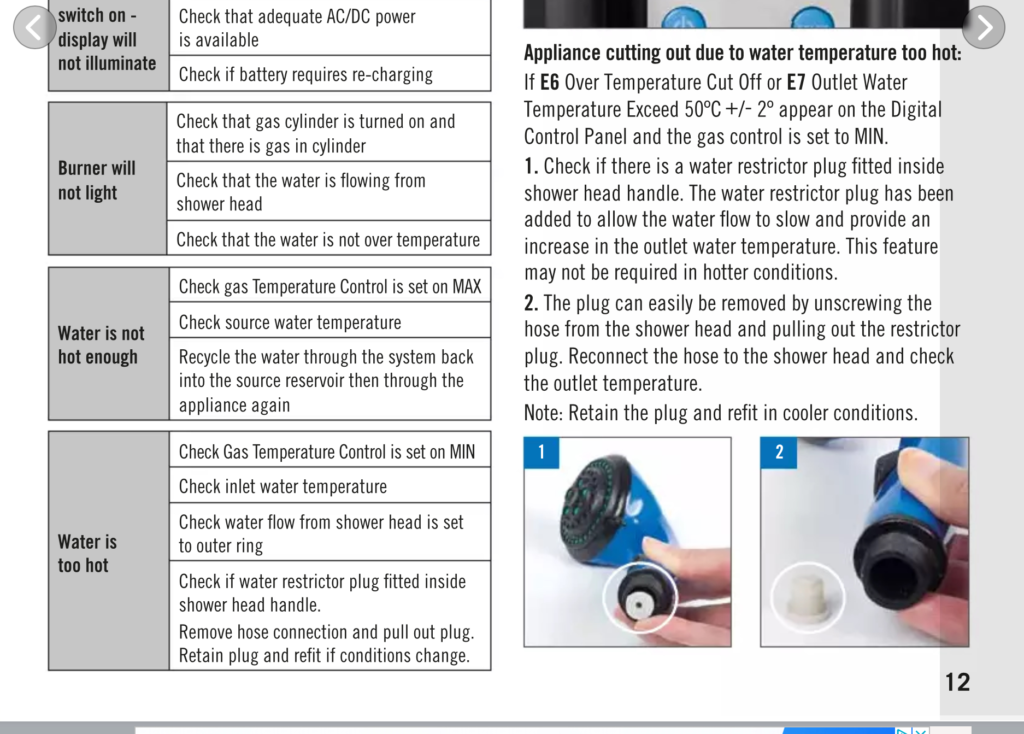

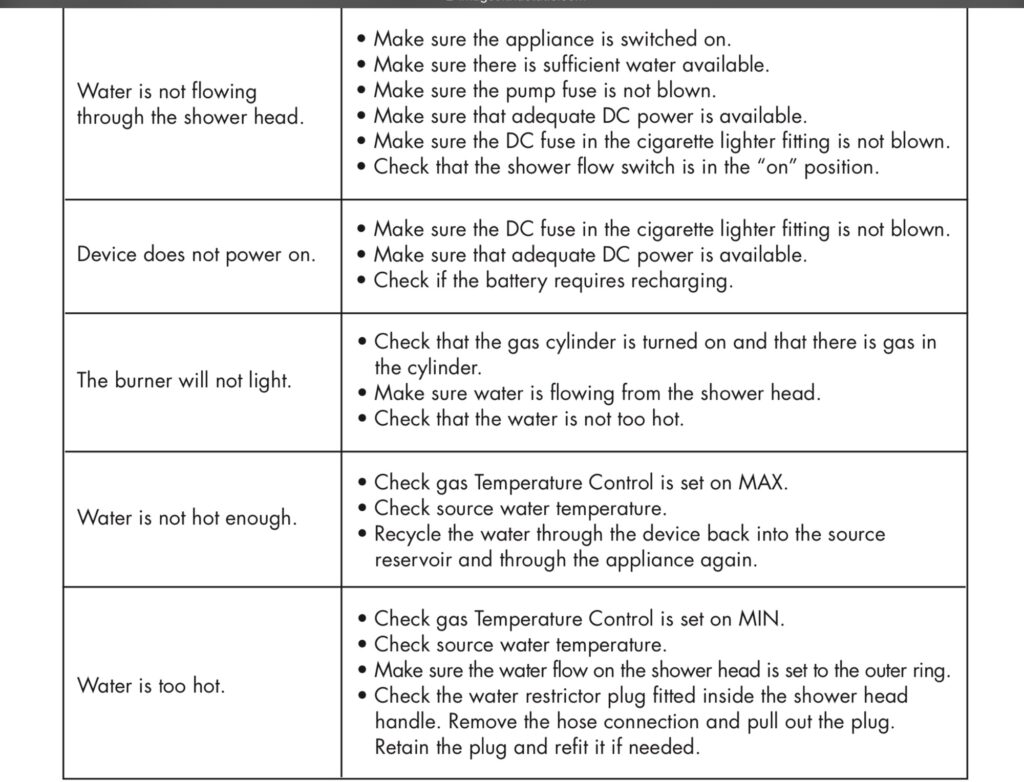

I have owned this unit for 8 years and suffered many small issues yet they feel catastrophic while camping. My issue at hand is that the water temp exceeds desired setting and gets too hot! It can cause an E7 error which is where the machine auto shuts down to prevent scalding burns.

⛔️When I experienced these issues I was camping during a regional heat wave where temps were exceeding 86-95+ degrees for day time highs.⚠️ I make an effort to avoid camping during extreme heat.

🌟Start from the outside and work into the control board.

Ambient Temperature

The first place to start is with the source water!

If the source water has been heated by direct sun light and by naturally elevated ambient atmospheric temperatures then this can lead to increased water output temps exceeding desired temp. So if the water is already heated to 85-90 degrees then the propane will very quickly heat it even further to 116-125+ degrees.

Solution #1. Remove the propane canister and run the shower without the canister. This is a fast fix for in the field use.

- Although cumbersome and awkward to remove the propane tank. another option is to order a control valve gas regulator that allows for the propane to be turned off without removing it. This also allows for pre heating the water by recycling water to the desired temp and then turning off the gas via the gas regulator. See below section on appropriate rated Gas Regulators.

Solution #2. Remove the internal water pressure reducing regulator. It is important to remember to reinstall the regulator.

Exhaust Heat and Recycling Water

Both sides of the shower have heat exhaust vents. If you place your water source directly next to these vents then the water will be heated by the exhaust vents. You want your source water as cold as possible if using the propane tank during warmer ambient temperatures. Try placing the water source directly behind the shower unit instead of next to it.

It is a well known tip to put the shower wand head into the source water with the pump and to allow a minute or two to pass while the water cycles through the heating elements and pre warms to a desired starting temperature. This method is fantastic in colder camping conditions to pre heat the source water so that it can reach those higher heat temps that otherwise are unattainable. However this too can lead to excess undesired heat temps during the warmer months. So it is best to simply remove the gas canister during excess ambient temperatures and allow the source water to heat up in direct sun light or via the ambient atmosphere.

To test these issues use a water source such as a jerry can or bucket of cold water. Place the water behind the shower unit. Holding the shower wand over a separate and empty bucket start the shower. Watch for the temp changes and if the temp stabilizes and no longer triggers an E1 or E7 code than the solution is simple. Do not place the water source directly next to the heat exhaust vents and or remove the gas canister when using in extreme ambient temps above 85 degrees.

Making these two changes were the solution to my issue!

Trouble Shooting

If the issue persists..

#1. Is the auto self regulator safety cut off switch in tact? If the sensor detects temps exceeding 125 degrees and auto shuts off giving an E7 code then it is working as it should.

#2. Is the flame shut off sensor in tact? When putting the shower wand into the “off” position does the flame auto turn off? If it is in working order then the #9 water flow feedback sensor is in tact.

With the internal safety features all working this would lead me to look for a bad gas regulator.

- Gas regulator

- Gas valve assembly

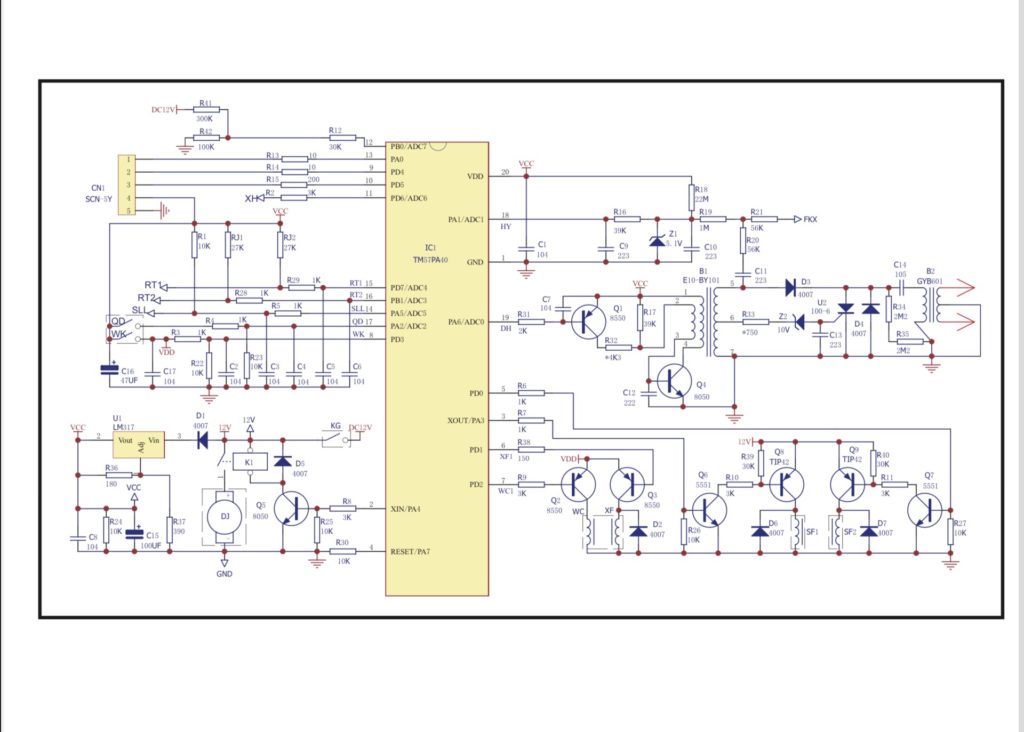

- Relays on control board

The only way to test this hypothesis is by a) switching propane sources and b) purchasing a replacement gas regulator.

Replacement Gas Regulator

The gas regulator can become clogged, cracked, or just simply defective. It is recommended to replace the gas regulator every 15-20 years or sooner if an issue is suspected. Replace with a regulator rated as;

- 18,000 BTU rated (verify your owners manual or rear sticker on the unit)

- 1” female pipe thread (inlet)

- 3/8″ female pipe thread (outlet)

- Low Pressure 11″ W.C. setting

- 1/2 PSI output

- 90 degree connection

Surprisingly there are not many regulators compatible within this categegory. ⛔️⚠️ It is important to recognize that the existing gas regulator has a proprietary adapter attachment that allows it to hook onto the shower. This adapter is threaded in and must be removed from the gas regulator and attached to any new regulator.

There is the Mr. Heater 11410 regulator and with a lot of searching a control valve gas regulator can be found.

Gas Valve Assembly

The internal gas valve assembly is the internal mechanism that increases and decreases the flow of propane and is controlled by the knob on the front of the shower. The next likely culprit that can cause an issue is the gas valve assembly. I have outlined it-here in the diagrams A & B.

- Listen for a hissing sound When you hit “start” or other propane appliances, listen for a loud hissing noise. This indicates a gas leak.

- Spray with soapy water Spray a mixture of dish detergent and water around your gas valve assembly (avoid electronics) and hoses. If you notice water bubbling, you likely have a gas leak.

- Check for frost or ice Frost or ice forming on any hoses connected to your tank could indicate a high concentration of propane in the air.

Also check all electrical connections and most important is to test the control board relay to make sure it does not need replacing.

Sensing pin #9

This must be the water flow sensor which triggers the igniter to turn off when the flow of water stops.

If the igniter is not turning off when the shower head wand is in the “off” position I would suspect a loose or faulty #9 sensor. If the temperatures are exceeding the safety regulator switch of 125 degrees then this may need replacing. Testing the relays requires the use of a multimeter.